The heat aging test chamber is an essential tool used for evaluating the heat resistance of electrical insulating materials, conducting gas aging tests on electronic components and plasticized products, and assessing how well materials perform under high-temperature conditions. In this article, I’ll share some important tips to help you use the heat aging test chamber safely and effectively.

1. Avoid opening the door unless it's absolutely necessary during operation, as doing so can cause fluctuations in temperature and affect test accuracy. It may also lead to potential safety risks.

2. When installing the test chamber, make sure the casing is properly grounded. Failure to ground the unit could result in electric shock if a fault occurs.

3. If you are testing hot samples, always use an external power supply to control the power of the test item. Never connect it directly to the main power source to prevent damage or hazards.

4. Regularly check the circuit breakers and over-temperature protection devices, as they are critical for ensuring the safety of both the equipment and the operator.

5. When placing test samples inside, ensure that the total cross-sectional area of the samples does not exceed one-third of the working space at any given point perpendicular to the airflow direction. This helps maintain even heat distribution.

6. It’s normal for the test chamber to emit some smoke or odor during the first week of operation. This is due to the lubricating oil used in the steel parts, which may burn off when exposed to high temperatures for the first time.

7. After completing the test, do not open the chamber door immediately. Sudden exposure to air conditioning or hot air can be uncomfortable or even dangerous. If you need to remove the samples right away, always wear insulated gloves to avoid burns.

8. Place all samples evenly within the effective testing area to ensure consistent and accurate results. Avoid overcrowding the chamber, as this can interfere with airflow and heat distribution.

9. Always turn off the main power switch when the test chamber is not in use. This helps save energy and reduces the risk of accidents.

10. Before operating the heat aging test chamber, take the time to thoroughly read the user manual. Understanding the instructions will help you operate the equipment correctly and safely.

By following these tips, you can maximize the performance of your heat aging test chamber while maintaining a safe working environment. Whether you're a technician or a researcher, proper handling and maintenance of the equipment are key to achieving reliable and repeatable test results.

Hello, grid charcoal roast *, in addition to baking, but also to prepare smoke-free special charcoal. In addition to the fire burning charcoal, in the barbecue process to continue to add charcoal to maintain the heat. Although this method can sometimes be "angry" and may even make people angry at other times, it is closer to nature and the food cooked by charcoal at high temperature will have a special fragrance. Charcoal grilling definitely tastes better than electric grilling, and it feels different. Electric grilling is just not that strong. However, there are many things to prepare for charcoal barbecue, and it is easy to get dirty. If you don't care about these, it is also very good to get a charcoal barbecue. If it is used at home, of course, the electric barbecue is convenient and clean. But if you want taste and fun, or charcoal is better.

| Name | Camping Stainless Steel Grill |

| Material | Stainless steel |

| Size | 350*350*120mm |

| Packing | Pallet/carton/wooden box packing |

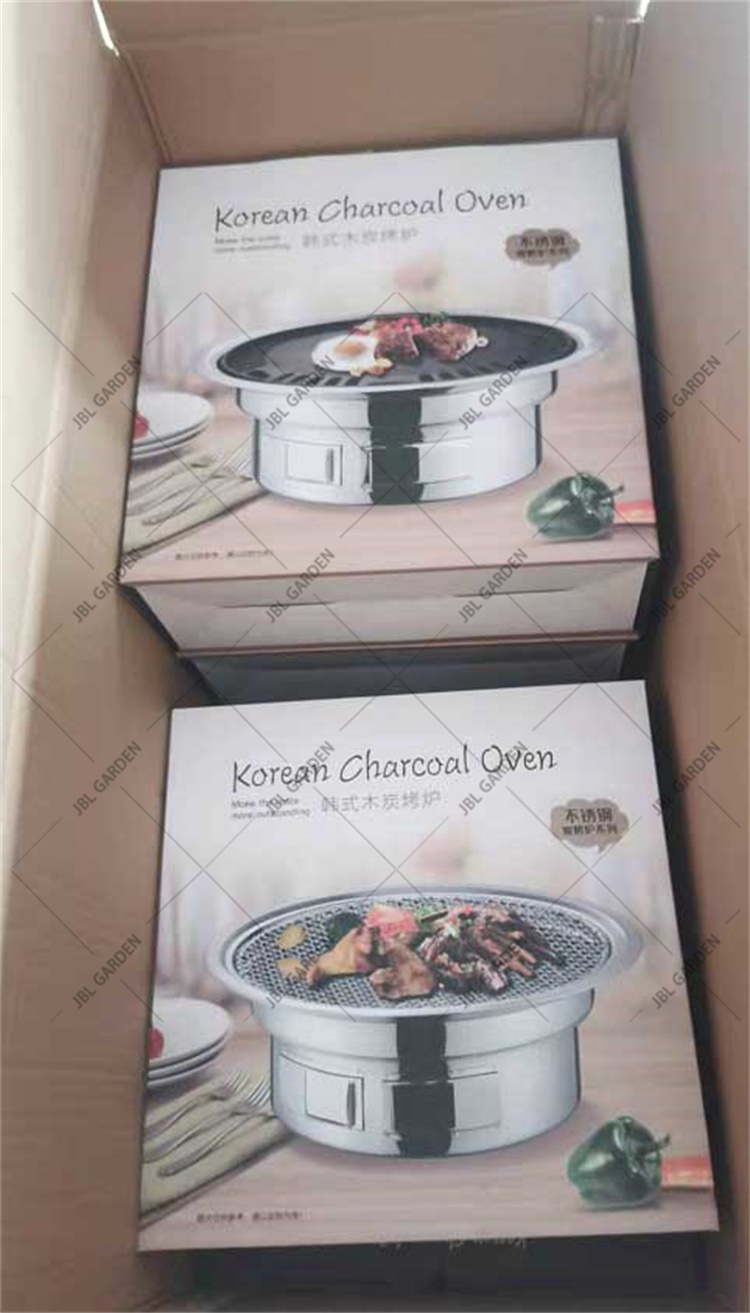

Packing

Packing will by carton.

Stainless Steel Bbq Grill,Steel Grill,Stainless Steel Grill,Stainless Steel Bbq

Henan Jinbailai Industrial Co.,Ltd , https://www.gardensteelarts.com